"EngiFlow360 delivers professional CRM solutions with a responsive and technically strong team."

We don't just track

customers. We track machines.

Generic CRMs treat every sale like a transaction. EngiFlow360 treats every sale as the start of a machine lifecycle—with years of service history, warranty rules, and renewals.

Serial-number tracking • Warranty + AMC workflows • Field service ready

Track from production

to scrapping.

Every serial number gets a timeline—sales, installation, warranty, AMC, and replacements.

Manufacturing & Sales

Machine is produced and assigned a unique Serial Number. Sold to customer via Direct Sales or Dealer.

Installation & Commissioning

Engineer visits site, installs machine, uploads photos, and activates Warranty start date.

Warranty & Support

System tracks warranty logic (e.g., 1 year parts, 2 years labor). Auto-validates claims against coverage.

AMC & End of Life

Convert warranty to Annual Maintenance Contract (AMC). Track machine aging for Buyback/Replacement opportunities.

Stop breakdowns

before they happen.

Our "Zero Breakdown" module uses logic-based scheduling to ensure machines are serviced exactly when needed.

-

Running Hours Integration

Integrate with IoT or allow customers to input meter readings. Service triggers at 500 hrs, 1000 hrs, etc. -

Calendar Schedules

For non-IoT machines, set recurring quarterly or monthly visit schedules automatically. -

Parts Forecasting

Know exactly which kits (Oil filters, O-rings) are needed for the upcoming 2,000-hour service.

Hydraulic Press #44

Your factory-to-field

network,

connected.

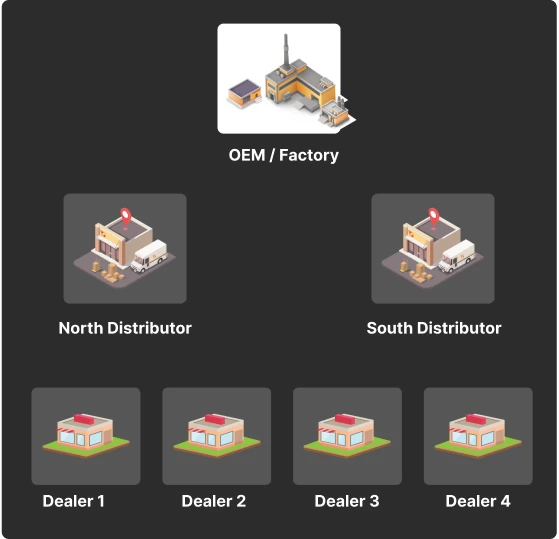

OEMs rarely sell alone. EngiFlow360 connects your Factory to your Distributors, Dealers, and Retailers in a single hierarchy.

Your factory-to-field

We understand your industry first — so the CRM works the way your business actually runs.

Custom-Built Solutions

We understand your industry first — so the CRM works the way your business actually runs.

Easy-to-Use & Scalable Platforms

Simple for teams today, powerful enough to grow with you tomorrow.

Dedicated Support & Implementation Guidance

We don’t just deliver software — we stay with you until success becomes routine.

Know your machines.

Because we structure data around the machine, you get insights that other CRMs can't provide.

-

Component Failure Analysis

Identify which part (e.g., Motor Model X) fails most often across all machines. -

Service Profitability

Track revenue vs. cost for every AMC contract to ensure profitability. -

Engineer Efficiency

Measure 'First Time Fix Rate' and average travel time per engineer.

Failure Rate by Component

Data aggregated from 1,200 active machines

Real results from teams running EngiFlow360 daily.

"Professional support and a powerful system that brought structure, efficiency, and cost savings to our business."

"Backed by deep domain expertise and reliable support, the system’s timesheet and incident modules deliver real value to our business."

"EngiFlow360 makes it easy to manage leads, accounts, and sales, with structured data, better visibility, and tailored support for our team."

"We’re very happy with EngiFlow360. The team is professional, responsive, and understands both business and technical needs."

"EngiFlow360 is simple, user-friendly, tailored to our needs, and backed by fast, dependable support."

"Our experience with EngiFlow360 has been very positive, with consistent support ensuring smooth operations."